Fluid Power Academy

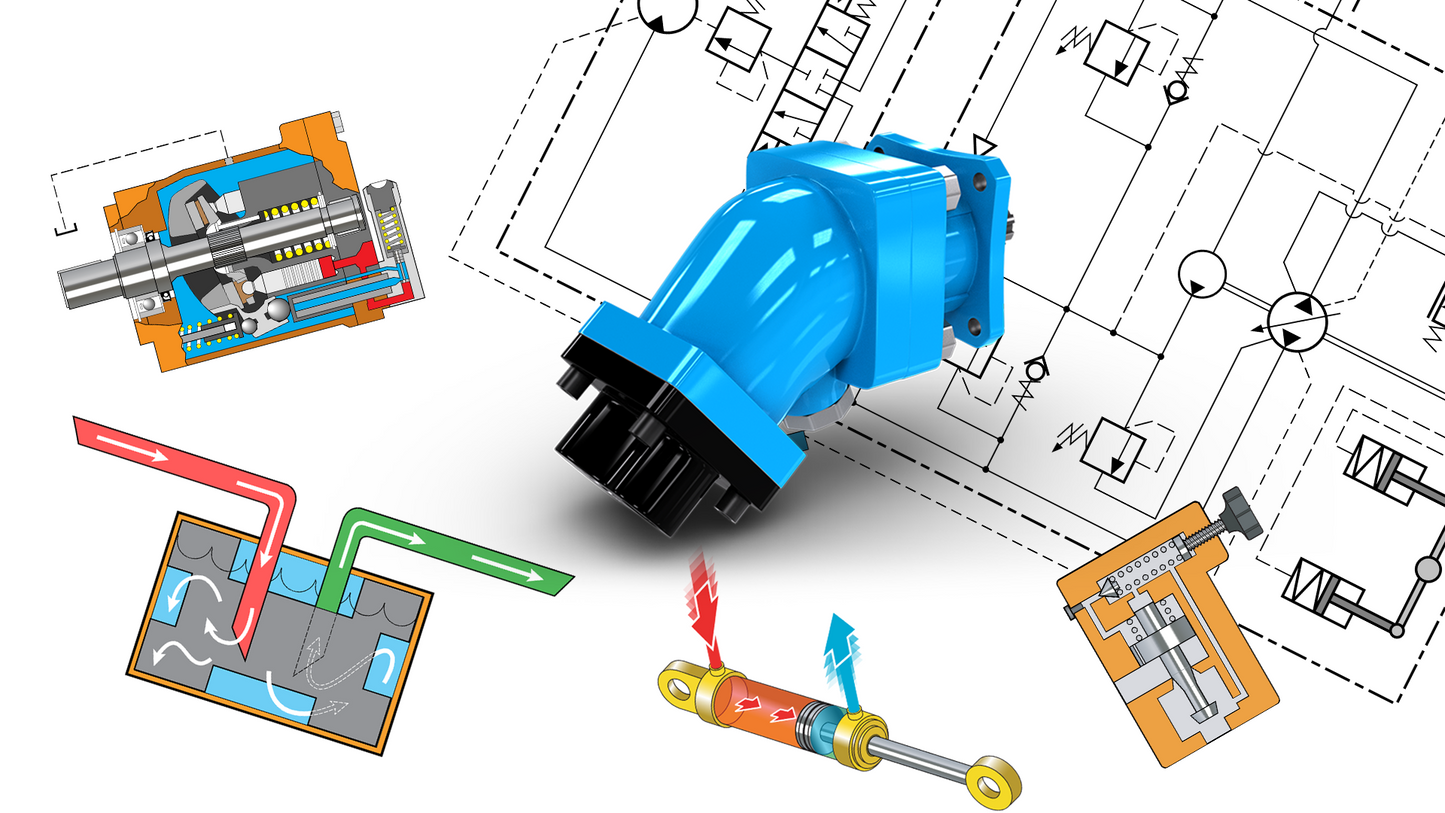

Practical Hydraulics Course

Practical Hydraulics Course

Couldn't load pickup availability

Unlock the secrets of hydraulic systems and ensure safety with our comprehensive 10-hour Hydraulics Safety and Training Course. This expertly designed program, featuring lessons created under the direction of FPTI™'s founder, Rory S. McLaren, provides in-depth knowledge and practical skills essential for anyone involved in the management, operation, or maintenance of hydraulic systems.

EXPIRES: 90 days after purchase

AVERAGE TIME TO COMPLETE: 10 hours

Course Lessons:

00 - The Lethal Strike

Learn the critical steps for the pre-hospitalization management of high-pressure injection injuries, an increasingly common and dangerous issue.

01 - Basic Hydraulics Safety

Master general safety practices, including manufacturer’s warnings, high-pressure hydraulic categories, stored energy, and lockout procedures.

02 - Introduction to Hydraulics

Familiarize yourself with hydraulic terminology, system components, diagnostic equipment, and the differences between open-loop and closed-loop systems.

03 - Oil Storage, Conditioning, and Transmission

Understand the purpose, types, and symbols of hydraulic reservoirs, filters, screens, coolers, and heat exchangers. Learn oil selection criteria, sampling requirements, and safety procedures for hose and line replacement.

04 - Hydraulic Pumps

Discover how hydraulic pumps work, understand pump volumetric efficiency, and identify ISO symbols for fixed and variable displacement pumps.

05 - Directional Control Valves and Pressure Relief Valves

Explore the functions and types of directional control valves and pressure relief valves, including their configurations and ISO symbols.

06 - Hydraulic Actuators

Learn about the purpose and function of hydraulic motors and cylinders, and how to identify their ISO symbols.

07 - Hydraulic Control Valves

Understand orbitrol steering valves, check valves, and shuttle valves. Learn to identify their ISO symbols and components.

08 - Miscellaneous Hydraulic Components

Get to know hydraulic accumulators, diagnostic instruments, oil selection, and proactive maintenance schedules for hydraulic systems.

09 - Open-Loop Hydraulic Systems and Schematics

Grasp the function of open-loop hydraulic systems, read schematics, and understand the concept of “power-beyond.”

10 - Closed-Loop Hydraulic Systems and Schematics

Learn the components and functions of closed-loop systems, the importance of flushing/hot oil shuttle valves, and how to read schematics.

11 - Pressure Compensated and Load Sensing Systems and Schematics

Understand pressure compensation and load-sensing systems, their symbols, schematics, and the effects of additional components.

Course Features:

· Knowledge Checks: Each lesson includes multiple knowledge checks to reinforce learning.

· Final Tests: At the end of each lesson, you will take a final test with three attempts to achieve a passing score of 80% or higher.

Course Access Disclaimer

This online course is intended for personal use only and may not be shared, distributed, or integrated into any institutional Learning Management System (LMS) without prior authorization. Course access is valid for 90 days from the date of enrollment, and all coursework must be completed within this timeframe. Extensions will not be granted.

For inquiries regarding institutional licensing or LMS integration, please contact us at 801-908-5456.

Share